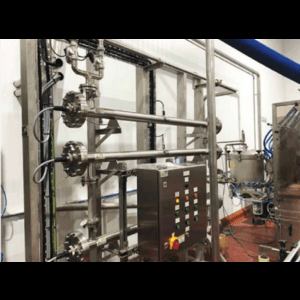

Liquid Disinfection

The disinfection of liquids utilizing UV-C is common place throughout the world. In effects which are detrimental to health and the environment. UV-C technology is the better alternative to chlorine disinfection. The intensively researched and technologically mature tubing, being treated by the UV-C light. The number of UV-C lamps employed vary according to amount, flow rate and The deployment of chlorine chlorine dioxide, hypochlorite and other chemical substances to disinfect liquids can result disinfection method with ultraviolet light is adapted from the natural action of sunlight. The light necessary for UV-C disinfection is generated in special UV-C lamps. A watertight tube made of quartz glass which allows the UV-C light to pass through surrounds each lamp. The liquid to be disinfected runs past the quartz transmittance of the medium. UV Technology's systems are suited for the disinfection of drinking water, process water, waste water, salt water, ultrapure water and other translucent fluids, e.g. sugar syrup. Other uses of water disinfection include the treatment of wet equipment parts such as dehumidifiers and rotary spray humidifiers in air conditioning equipment. The rate of disinfection is up to 99.99%+, depending on the UV-C dosage. UV Technology's UV-C systems provide non-chemical disinfection for process, product water and other liquids in a wide range of applications. INDUSTRIES BENEFITING FROM UV TECHNOLOGY: •Meat and poultry processors. • Dairy. •Water & soft drink processors & bottlers. • Breweries & wineries. • Processed & pre-packaged foods • And many more... APPLICATIONS INCLUDE •Pre-treatment disinfection. •Cooling media (Brine chillers etc). •Direct contact fluids and ingredients. •CIP, bottle rinse or wash waters. • Tank headspace and venting. •Grey water systems.